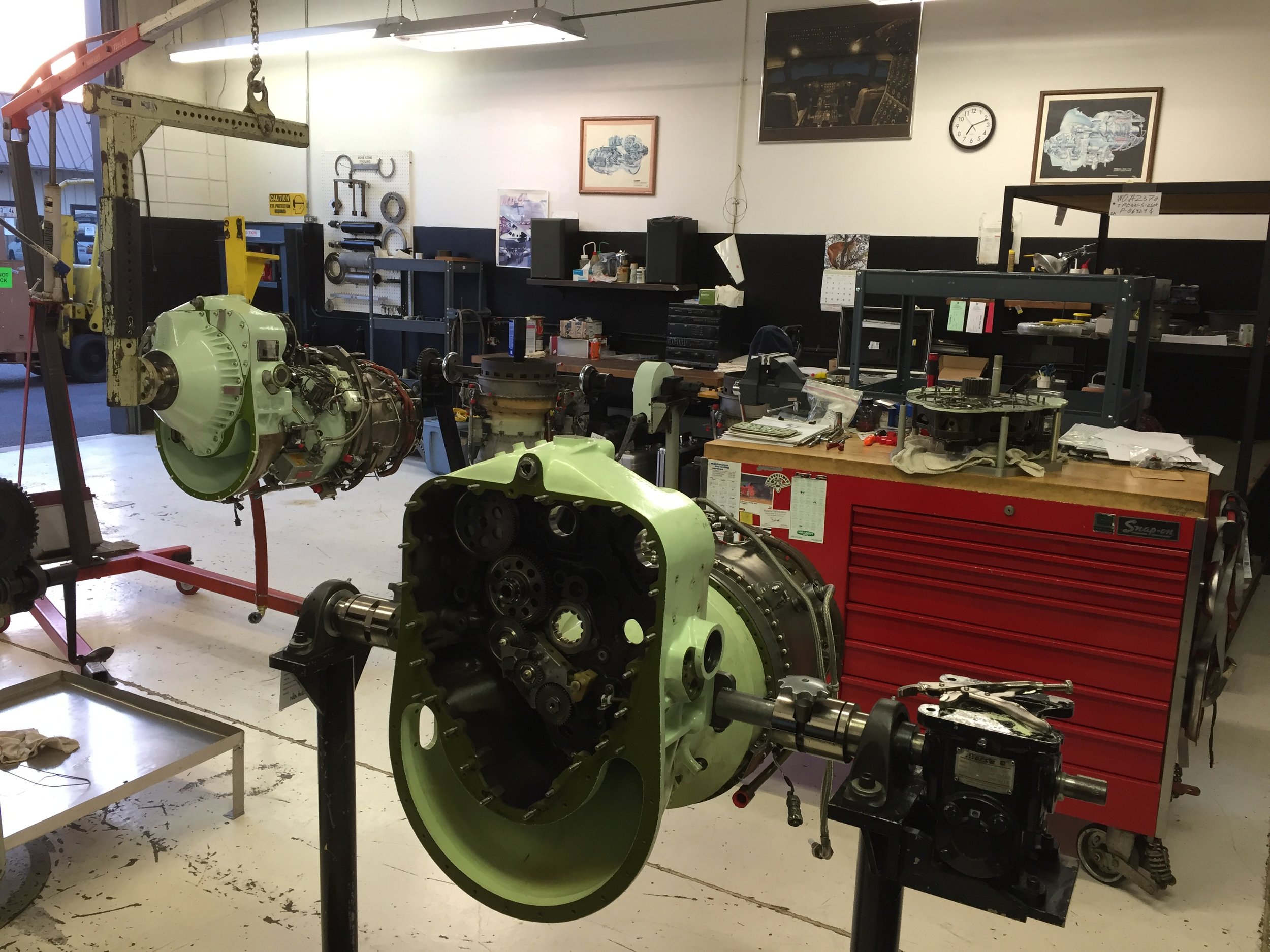

Engine Overhauls and Maintenance

Honeywell TPE331 & Pratt & Whitney PT6 Engine

Hancock Enterprises, Inc. has been your primary source for all things turbine since 1982. We are a Certified FAA and EASA Repair Station and specialize in the maintenance and repair of the Honeywell TPE331 and the Pratt and Whitney PT6 turbine engines. We also offer a HELP Program for the aging Honeywell Pre Century engines. We offer an onsite Hot Section Inspection and repair on all PT6 Engines. We at Hancock Enterprises, Inc. understand that time is money and we offer a 24/7 AOG service to help aid in getting your aircraft back up and running as soon as possible. We work on your schedule, not ours.

We also offer Borescope Inspections for both Honeywell TPE331 and Pratt & Whitney PT6 Engines. This will show you the condition of your engine and can be performed either at your facility or ours. This inspection can be performed for your own peace of mind, for pre-purchase inspections, at nozzle changes, or to comply with your Pratt and Whitney or Honeywell engine maintenance programs.

Contact our team to get a quote on repairing or overhauling your PT6 or TPE331 engine

Check to see if we service your engine model.

Some common engine areas of emphasis:

Overhaul

Gearbox Inspections

Hot Section Inspections

CAM Inspection

TBO Extensions

Engine Conversions

Lighting Strike Inspections

Prop Strike Inspections

Corrosion Inspections

Insurance Claims

Borescope Inspections

Test Cell

Lebow and Recomp Runs

Vibe Surveys

FOD

DOD

Hot Starts

Bog Downs

Thermal Distress

Sudden Stoppage

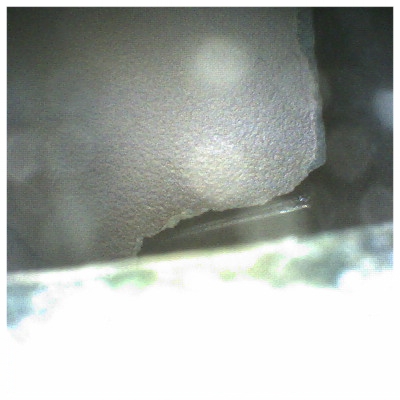

Fuel Nozzle Program

Fuel Nozzle Maintenance and Overhaul is the major factor affecting the life and performance of turbine engine hot sections. Honeywell recommends replacement every 400 hours for simplex nozzles and 350 for duplex nozzles. Prat and Whitney recommends replacement at 400 hours for simplex and duplex nozzels. We recommend replacement every 300 hours for both types of nozzles for both types of engines. This will help extend the life of your hot section and keep it from looking like the hot section pictured. Being diligent about this critical maintenance procedure will save the operator money over the life of the hot section. Borescoping at nozzle changes can help monitor hot section wear and help catch damage before it becomes a costly repair.

Our Fuel Nozzle Overhaul and Exchange Program for both Pratt and Whitney PT6 and Honeywell TPE331, that will help get you back up and running faster with a quicker turn around time if time is a factor for you. Contact us today for your next PT6 or TPE331 fuel nozzle overhaul.

Digitalized prop stand test cell unit on premises.

Each completed engine undergoes a full operational check prior to shipment. Included are torque setting determinations with calibrated Lebow Equipment. Depending on the work scope, we are equipped to perform with our Computer-based Recompensation Equipment. These fine-line tests and setups ensure that each engine delivered to the customer meets the highest standards of performance in the field.